Technology plays an important role in many areas of our lives, it has made it possible for information access to be faster and faster, producing a transformation in the way we consume and relate with data.

Business environment is getting more involved in this constant technological evolution. The industrial sector has been incorporating gradually greater uses of automation and connectivity.

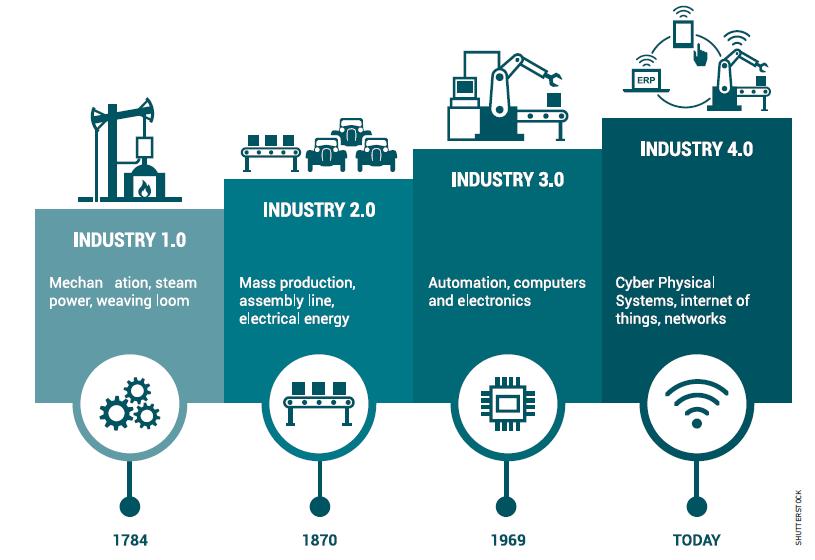

The concept of Industry 4.0 refers to some aspects that you have surely heard: fourth industrial revolution, smart industry, interconnected industry or cyber industry.

All these definitions refer to the use of technologies to make the manufacturing process more agile, flexible and noticeable to customers.

But surely you are interested in knowing what a fourth industry revolution entails, what its benefits are and how you can implement it in your business.

What is industry 4.0?

The concept of industry 4.0 refers to the so-called fourth industrial revolution.

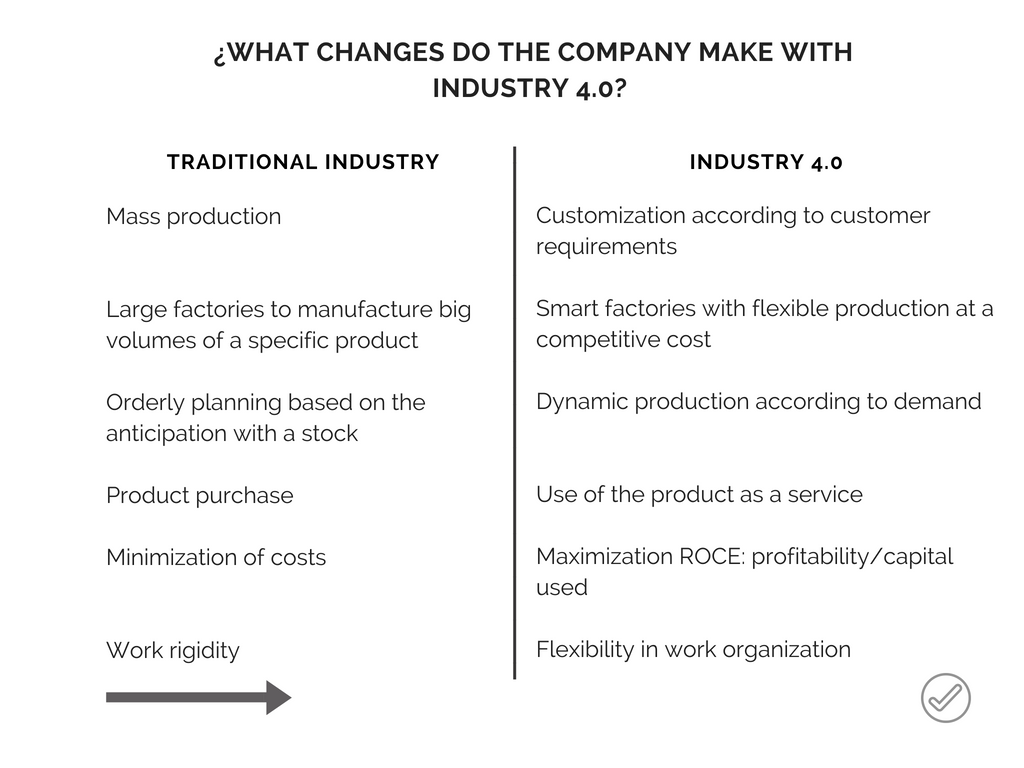

This involves the digital transformation of the industry with the integration and digitalization of all the industrial processes that make up the value chain, characterized by its adaptability, flexibility and efficiency that allows to cover customer’s needs in the current market.

Industry 4.0 represents a qualitative leap in the organization and control of the entire chain value throughout the life-cycle of the manufacture and delivery of the product. This produces a paradigm shift for industries as Deloitte University Press explains in its video.

Industry 4.0 uses digital technologies to react more quickly to market changes, offer more personalized products and increase operational efficiency.

This paradigm shift in Industry 4.0 is based on the following principles:

![]() Interoperability: the communication ability of all the elements of the factory, cyber-physical systems, robots, corporate information systems, smart products and the people, as well as third-part systems.

Interoperability: the communication ability of all the elements of the factory, cyber-physical systems, robots, corporate information systems, smart products and the people, as well as third-part systems.

![]() Decentralization: the capacity for the design of autonomous sub-processes within the factory with cyber-physical elements with the capacity to make decisions autonomously.

Decentralization: the capacity for the design of autonomous sub-processes within the factory with cyber-physical elements with the capacity to make decisions autonomously.

![]() Real-time analytics: the ability to collect and analyse large amounts of data (Big Data) that allow the monitoring, control and optimization of processes, facilitating any result and decision derived from the process immediately and at every moment.

Real-time analytics: the ability to collect and analyse large amounts of data (Big Data) that allow the monitoring, control and optimization of processes, facilitating any result and decision derived from the process immediately and at every moment.

![]() Virtualization: the ability to generate a virtual copy of the fabric by collecting data and the modelling industrial processes (physical), obtaining virtual plant models and simulation models.

Virtualization: the ability to generate a virtual copy of the fabric by collecting data and the modelling industrial processes (physical), obtaining virtual plant models and simulation models.

![]() Service orientation: the ability to transfer the new value generated to the customer in the form of new services or improved services with the exploitation of new disruptive business models.

Service orientation: the ability to transfer the new value generated to the customer in the form of new services or improved services with the exploitation of new disruptive business models.

![]() Modularity and Scalability: the flexibility and elasticity to adapt to the needs of industry and business at all times, with the ability to scale the technical capacity of the system in accordance with the technical requirements required by the evolution of business demand in each case.

Modularity and Scalability: the flexibility and elasticity to adapt to the needs of industry and business at all times, with the ability to scale the technical capacity of the system in accordance with the technical requirements required by the evolution of business demand in each case.

Source: Ronald Berger

What are the benefits of industry 4.0?

- Greater productivity and better management of resources.

- More efficient decision-making based on real information.

- Optimized and integrated productive processes

- Increase the flexibility to achieve a mass production and personalized in real time.

- Direct communication between clients and organizations, which means that we can better understand what customers need.

- Reduction of manufacturing time both in the design of new products and in the merchandising of these.

- Reduction of the percentage of defects or shrinkage in the factories since it will be possible to test the prototypes in a virtual way and the assembly lines will be optimized.

If you think that Industry 4.0 is still far away, you may be interested in how some of our customers have already applied a solution for remote management and control of the activities of their production plants.