Industries are part of a market in continuous evolution, in which the constant optimization of processes is required to improve decision making. On this basis, IoTsens has developed a customized solution that allows obtaining a total vision of the production of industrial plants through any device in order to optimize the production process.

Industries are part of a market in continuous evolution, in which the constant optimization of processes is required to improve decision making. On this basis, IoTsens has developed a customized solution that allows obtaining a total vision of the production of industrial plants through any device in order to optimize the production process.

CLIENT

Our customer is a leader in the packaging sector and has industrial plants distributed on the national territory. Its business career is characterized by offering a quality product, so they have decided to make the digital transformation to Industry 4.0 to offer added value in the quality of their products.

SOLUTION

After conducting a detailed study of the characteristics of the installation, as well as the needs and requirements of the client, IoTsens has developed a solution that allows supervising, monitoring and analyzing the activity and production of their industrial plants.

The first step was to adapt the data collection process in order to achieve that in the most robust way possible, the solution was able to read the data specifically for each manufacturer since the plant is composed by different machines manufacturers with different criteria to establish the structure of their data.

Secondly, the platform performs operations to unify different data that, due to its characteristics, may be in different formats.

After this, the information can be treated uniformly, a necessary step to calculate and manage the production of the plant.

CLIENT

Our customer is a leader in the packaging sector and has industrial plants distributed on the national territory. Its business career is characterized by offering a quality product, so they have decided to make the digital transformation to Industry 4.0 to offer added value in the quality of their products.

SOLUTION

After conducting a detailed study of the characteristics of the installation, as well as the needs and requirements of the client, IoTsens has developed a solution that allows supervising, monitoring and analyzing the activity and production of their industrial plants.

The first step was to adapt the data collection process in order to achieve that in the most robust way possible, the solution was able to read the data specifically for each manufacturer since the plant is composed by different machines manufacturers with different criteria to establish the structure of their data.

Secondly, the platform performs operations to unify different data that, due to its characteristics, may be in different formats.

After this, the information can be treated uniformly, a necessary step to calculate and manage the production of the plant.

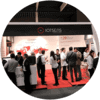

ARCHITECTURE

The system reads data from PLCs through different gateways, which send the data to the IoTsens platform. These data is processed and displayed on the IoTsens Smart Factory Web application.

RESULTS

The implementation of IoTsens SmartFactory generated the client multiple benefits that made an early return on investment: